MEGA-Drain™ – the “Moisture Eliminating Gravity Apparatus!”

We are excited to announce the launch of MEGA-Drain™ by Hallaton! Bringing our 30 years of geosynthetic installation experience, we have partnered with MEGA-Drain Corporation to offer their press-less, dry-stack tailings and water management system to our home in the Chesapeake Bay watershed and beyond as your exclusive East Coast installation experts.

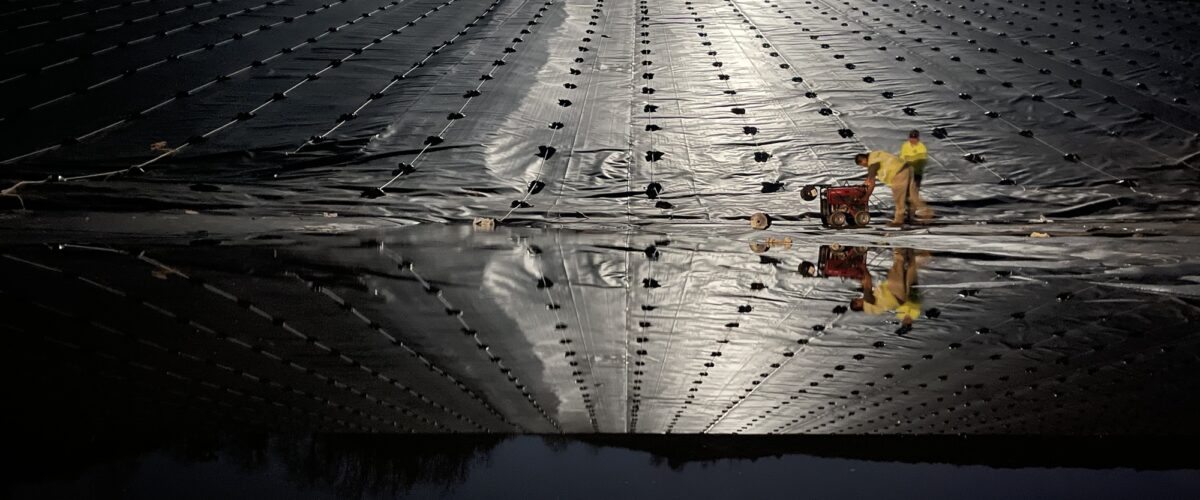

MEGA-Drain™ is the first “smart” drainage solution optimally engineered to dry stockpiled ore, recover decant, hold, and treat decant, and allow for dry-stacked tailings management without mechanical filter presses. Its multi-layered design leverages airflow, negative air pressure, and gravity to enable passive drainage, storing water underground in a non-reactive vault. With reduced costs, complexity, waste, and footprint requirements compared to traditional decanting methods, we believe the MEGA-Drain™ system will be the mining industry’s “best practice,” and we are honored to play a role in the bright future of responsible mining material processing, and stockpiling.

Applications:

- Tailings stream of Underflow / Overflow from cyclone discharge – recover water at the end stage of processing

- Production stockpiles from Radial Stackers / Cyclones / Trippers / Tunnels & Reclaimers

- Water Storage–lined impoundments with floating covers lasting 30 years!

Why MEGA-Drain™ ?

The MEGA-Drain™ system is scalable, modular, simply installed, and rapidly constructed. It reduces a project’s total requirements for water, does not require filter presses or the facilities to house them, and removes more moisture faster than filter-press-based solutions.

- Reduce stockpiled material moisture contents sub 5% to low single digits rapidly.

- Eliminate material rehandling.

- Reduce fuel consumption and carbon footprint.

- Reduce plant upset conditions with consistent low moisture feed stock.

- Reduce OPEX with discernable and accurate CAPEX for asset.

- Increase production 20 -35%.

- Increase EBITDA with measurable ROI.

- Increase plant/production options by increasing water reserves.

- Increase market capitalization.

Give us a call to learn how MEGA-Drain™ can help you turn water from a LIABILITY into an ASSET!