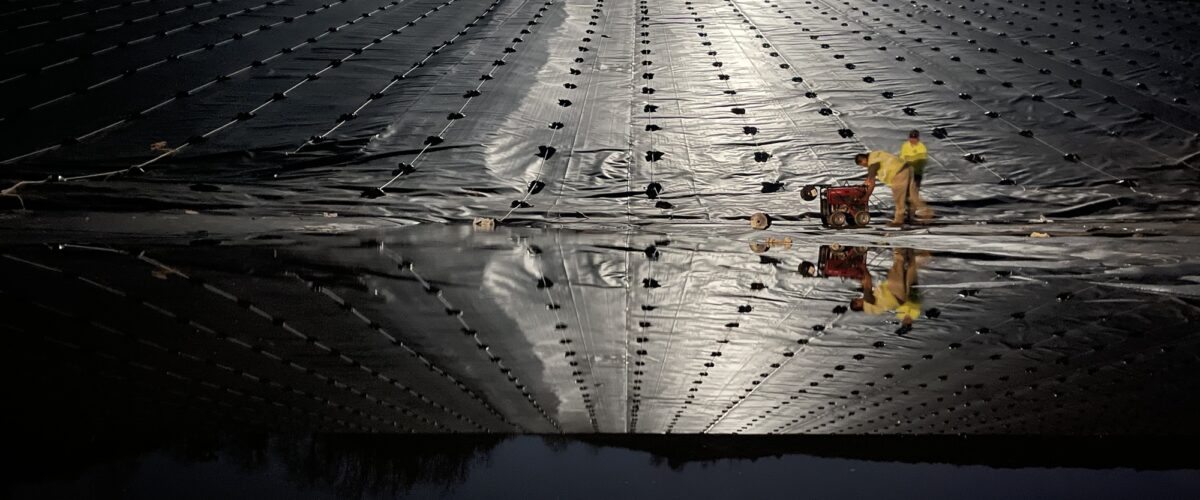

Hallaton Environmental Linings was contracted to provide and install a multi-layer geosynthetic liner system for a utility company in Kentucky. The final layer of the installed system was a fabric-formed concrete layer.

Multi-Layered Geosynthetic Liner System for Power Plant

A coal-fired power plant that is owned and operated by a regional utility company in Kentucky required the construction of a new impoundment and improvements to multiple existing impoundments to handle the residual cooling and run-off water. A multi-layered geosynthetic liner system was needed to bring the power plant in compliance with new federal regulations.

Fabric-Formed Concrete System

Covering 7 acres of various impoundments, Hallaton installed a geosynethetic liner system consisting of a GCL installed on a prepared subbase, 40 mil LLDPE textured geomembrane liner, 12 oz non-woven geotextile, and a 6″ fabric-formed concrete system filled with highly fluid concrete mix. Hallaton’s crew installed on average 120 cubic yards of the highly fluid concrete mix on a daily basis, meeting the requirements of the condensed construction schedule. The completed system will provide added protections to the environment and allows the owner to maintain the upgraded impoundments in a more efficient and cost-effective manner.

View Project Profile.