What Is Geomembrane?

Geomembrane is made from impermeable geosynthetic material. It consists of thin continuous sheets of polymers that can be manufactured in varying widths, thicknesses, and textures. The manufacturing process involves polymer resin, which is usually combined with different additives. It is either extruded or blown into sheets based on product specifications.

Types of Geomembrane

Flexible vs Non-Flexible

Geomembrane can be divided into a number of categories based on their primary features. Flexibility is one of the most important characteristics of the material. Flexibility helps determine how well the material will fit the area and how prone it is to cracks and tears. Highly strain-resistant geomembrane is considered flexible. However, non-flexible products have a semi-crystalline structure and are typically more rigid.

Reinforced vs Unreinforced

Geomembrane is further divided into reinforced and unreinforced categories. Although one might assume that reinforced geomembrane would always be best, some applications specifically call for a geomembrane without additional reinforcement. This is true, for example, when permanence in a buried application is essential.

Buried vs Exposed

Lastly, the choice of geosynthetics for a project often depends on whether it’s going to be buried or exposed. Not all geomembranes will hold up well in daily exposure to direct UV rays. Also, others degrade rapidly if buried or covered in gravel. You’ll want to ensure the product you choose is designed specifically for the type of application for which it’s being used.

Products Available for Installation

Depending on the parent resin used, there are several types of geomembrane products available. Hallaton has experience installing all types of geomembrane, including:

- HDPE (smooth & textured)

- LLDPE (smooth & textured)

- XR-5

- HDPE Pipe

- Hypalon

- Polypropylene/RPP

- RPE

- PVC

- EPDM

How Is Geomembrane Used?

There is a growing number of uses for geomembrane within a variety of markets. These include solid waste, mining, oil and gas, aquaculture, agriculture, power/energy, water treatment, water storage, ornamental and recreational ponds, transportation, etc.

With their extreme durability, geomembrane is a cost-effective solution designed to prevent the leakage of harmful contaminants or hazardous chemicals into surrounding environments. Their low permeability qualities make them effective barriers to protect the environment from various types of hazardous waste, such as leachate from landfills or by-products from coal-fired power plants.

In the 1980s, when the Environmental Protection Agency (EPA) began requiring solid-waste landfills to be lined, geomembranes became the number one solution to address this environmental mandate. Since then, they have been growing in popularity for other applications.

Within the United States, geomembranes are also commonly used for water storage, within waste water treatment facilities, for ornamental ponds, in agriculture and aquaculture, in oil and gas drilling operations, for coal ash disposal, and in various specialty applications.

Installation

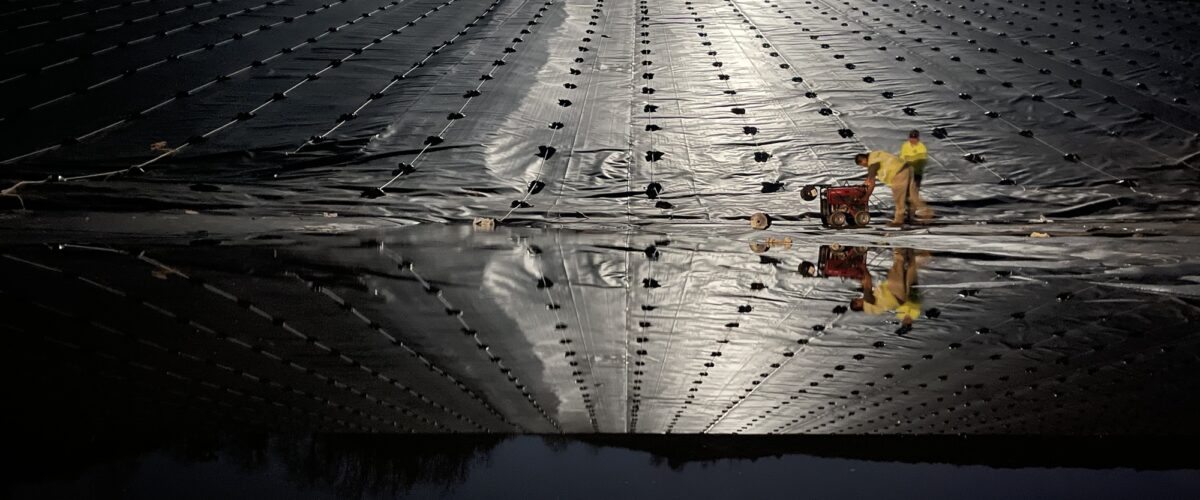

Geomembrane liner installation is a highly technical process. It requires proper welding equipment that is operated by certified welding technicians for a successful and lasting installation.

With more than 28 years of liner installation experience, Hallaton is an Approved Installation Contractor with several Certified Welding Technicians on each of our liner installation crews. We have installed nearly 2 billion square feet of geosynthetic lining material. Plus, we use the highest level of quality control measures to ensure proper seaming, good inspection, and a lasting installation.

Please see our HDPE and LLDPE Geomembrane Installation manual for more information.

If you have questions about geomembrane or have a project that requires expert installation skills, please contact Hallaton today.

We’ve Got You Covered!