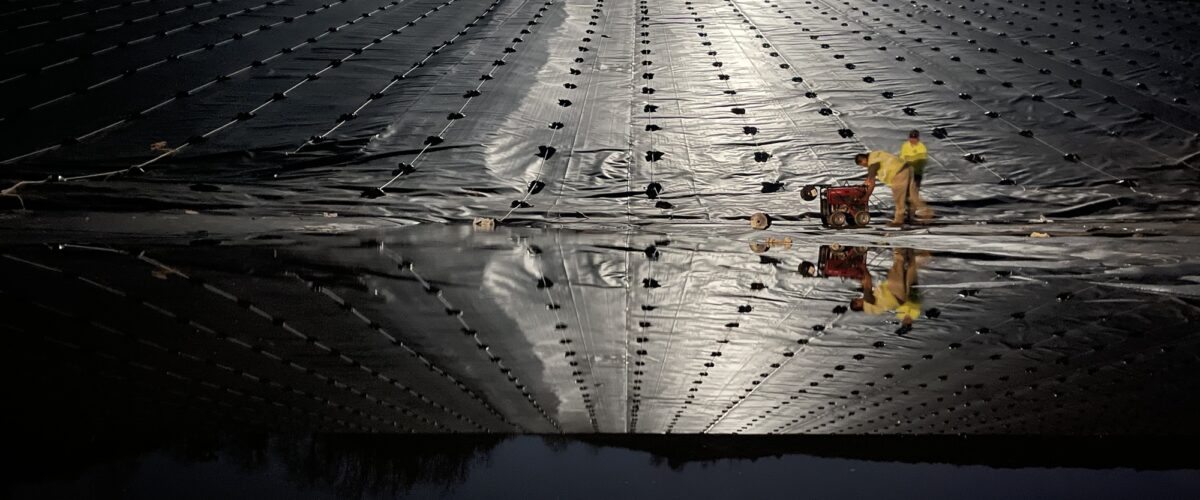

Safety is a core value at Hallaton Environmental Linings, and it’s something we do exceptionally well. Our employees are our most valuable asset, and providing a safe, accident-free work environment is critical to our overall success.

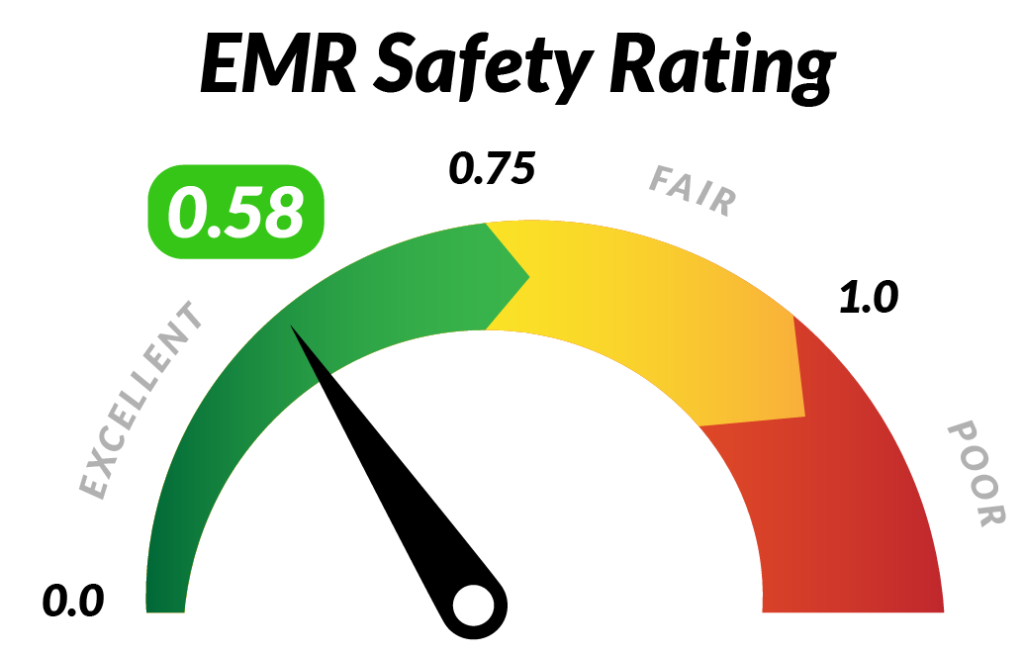

Our Current Safety Record

Health & Safety Training

Hallaton provides all employees with training based on our comprehensive Health & Safety Program. The training is designed to ensure that we maintain a healthy and safe workplace on all our projects, no matter the size or scope.

This program includes, but is not limited to:

- New Hire Orientation

- Drug & Alcohol Abuse Policy

- Installer/Technician Training w/ Certification

- HazCom Plan

- First Aid / CPR Training

- Daily Toolbox Meetings

- Quarterly Safety Meetings

- PPE Usage and Field Attire

- Equipment Safety Training w/ Regular Inspections

- Safety Documentation & Best Practices Review

- Worksite Audits

Safety Program

Hallaton works hard to ensure that safety is taken seriously by all employees. We utilize several industry-based safety program networks to document and train our employees, including ISNETWORLD, BROWZ, POWERSAFE, and AVETTA.

Employees receive OSHA’s 10-, 30- and 24-hr HAZWOPER training. The HAZWOPER training protects our workers on sites that have hazardous waste and teaches them how to respond quickly to emergencies. In addition to this, many of our employees also receive their TWIC (Transportation Worker Identification Credentials). We are committed to an accident-free workplace and have well-trained employees and systems in place to ensure that we maintain the highest levels of safety.

Quality Control

A lining system is only as strong as the seams that hold it together.

As an environmental lining’s leader, we ensure that all of the geosynthetics we install provide maximum protection to the land and water. We carefully follow the established industry standards for geomembrane installation and testing.

Prequalification Welding and Testing

The wedge welder (or fusion welder) is what we generally use to weld our main production lines on a jobsite. To qualify the welding equipment for use in the field, we run trial seams in the morning and afternoon. We test the seams’ strength for both peel strength and shear strength using a tensiometer. The welding machine is approved for use once it passes the trial seam testing.

Field Seam Non-Destructive Testing

Air Channel Test

The air channel test is a way to test a long seam without having to physically tear the liner apart. We close off both ends of the air channel and pressurize it to 30 psi. Five minutes later, if we have lost no more than 3 psi, then we consider it a passing test and the seam is approved.

Vacuum Box Test

While the main production seams are created by wedge welding, if we have to repair a liner, we use extrusion welding. We cover the damaged liner with a new piece of liner and use a hot air gun to heat tack it into place. Then we round down the edges and use an extrusion gun (or extruder) to seal the top liner to the bottom liner.

After that, we test the extrusion weld seam with a vacuum box to make sure it isn’t leaking. We apply a soapy solution to a strip of the seam and then place the pressurized vacuum box over it. If no soap bubbles appear, then the area is considered leak-free.

Quality Control Logs

The test results are recorded both in our quality control logs and on the liner itself. The technician who performs the test also marks his initials and the date on the lining. We are committed to following all of these industry best practices because we are passionate about our role in helping protect the environment.

Installation Manual

Download our installation manual, which describes the industry guidelines we follow for installing HDPE and LLDPE geomembrane. (PDF, 17 pages)